Plc Ladder Diagram Examples

The ladder diagram has and continues to be the traditional way of representing electrical sequences of operations. Ladder Diagrams And The PLC (on photo: Siemens modular programmabler controller SIMATIC S7-1500; credit: Wikimedia) These diagrams represent the interconnection of field devices in such. When a PLC is used primarily to replace relays, timers, and counters, it's hard to beat the simplicity and usefulness of ladder diagram programming.Their ability.

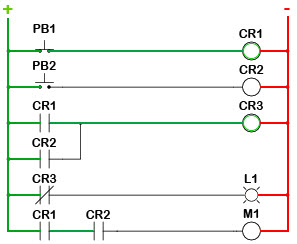

A wiring diagram, shown in figure 1, is an electrical print that shows connections of all components in a piece of equipment.tend to show a close representation of the interior position of electrical components in a control cabinet and/or circuit. Sometimes wire diagrams can closely represent a picture. The only difference is components are represented by electrical symbols whether they are NEMA standard or IEC standard symbols, whereas a pictorial will have a more realistic representation of an electrical component. A schematic diagram, shown in figure 2, is a type of drawing that illustrates the electrical connections and functions of specific circuit arrangements with graphic symbols.do not often show the physical relationship or layout of the components in the circuit; however, schematic diagrams are useful for understanding the sequence of operations or the operation of the circuit.Schematic diagrams are not intended to illustrate the physical size or appearance of the device nor the location. In troubleshooting, electrical schematics are essential because it enables a technician to trace the circuit and its function without regard to the actual location or physical size of the component.Figure 2. Schematic view of a Simple Circuit Ladder Diagram Definition. A ladder diagram, shown in figure 3, is a diagram that explains the logic of the electrical circuit or system using standard NEMA or IEC symbols.A is used to point out relationships between circuit components, not the actual location of the components.

Ladder diagrams provide a fast and easy understanding of the connection of electrical components in a circuit or operation.Figure 3. Ladder DiagramThe arrangement of symbols in ladder diagram should promote clarity and understanding.

Graphic symbols, abbreviations, and device designations are drawn per industry standards. The circuit should indicate the most direct path of logical sequence. Lines between the symbols can be horizontal or vertical but should be drawn to minimize lines from crossing each other.Ladder diagrams should not be confused with a one-line diagram. A one line diagram has only one line between individual components.

Ladder diagrams; however, often show multiple lines leading to and from components whether they are series or parallel connections. LADDER DIAGRAMS RULESThe ladder diagram, shown in figure 4, is easy to read since there are only two basic parts- the rails and the rungs. The rails are the two dark vertical lines that represent the power source to the control circuit. The control circuit voltage is usually rated at 12V-120V depending on the rated values of the loads connected in the circuit. The rungs are the horizontal lines that illustrate how the control devices and loads are interconnected to make up the control circuit.1.A ladder diagram translates similarly to a book.

Read the ladder diagram from left to right then up to down in order to understand the sequence of the operation.2. The loads in a ladder diagram are always and shall be connected in parallel on the rungs.3. The load is the last component connected to the right side of the rail unless there is a protective contact that opens the circuit in the case of an overload event.4. Control devices are connected between the left side of the rail and the load or other control devices and the load. Control devices are never to be connected from the left rail to the right rail. The result of this type of connection will result in a short circuit.Figure 4.

Omron Plc Ladder Diagram Example

Ladder Diagram.

Ladder Diagram

We will look at a PLC basic tutorial of a paint spraying station. Following the this PLC programming example should fully explain the procedure for developing the PLC program logic. Ladder will be our PLC programming language.We will be using the which comes with a simulator. This fully functional program is offered free of charge at automation direct.Define the task:What has to happen?Paint spraying system where boxes are fed by gravity through a feeder magazine one at a time onto a moving conveyor belt. Upon the start signal, boxes are pushed towards the conveyor by valve 1. This is a cylinder which extends and retracts which operates switches S1 and S2 respectfully.

Plc Ladder Diagram Examples Pdf

A spraying nozzle paints each box as it passes under the paint spray controlled by valve 2. A sensor (S3) counts each box being sprayed. When 6 boxes have been painted the valve 2 shuts off (paint spray) and valve 1 (cylinder) stops moving boxes onto the conveyor. Three seconds later the conveyor stops moving and the hopper with its load moves forward (valve 3) where it is emptied.

Ten seconds later the hopper returns to the original position.